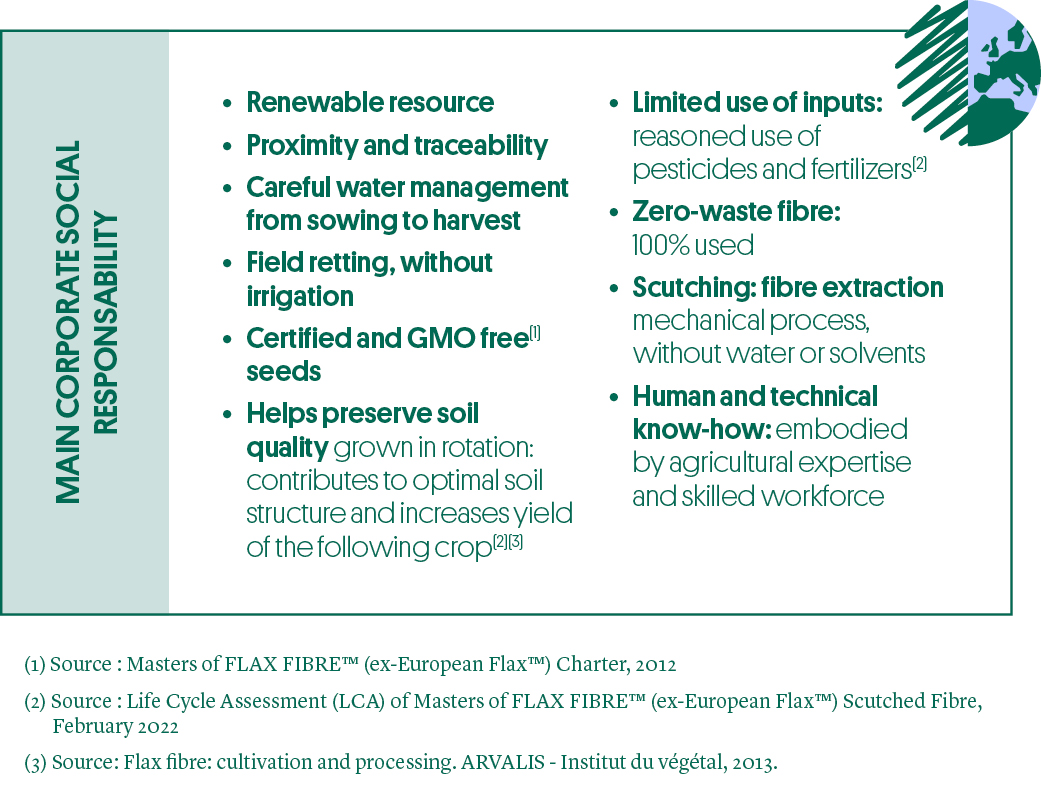

Environmental responsibility of European flax

European flax stands out for its many natural qualities that promote environmental conservation. It offers a sustainable and local alternative that is particularly well suited to today's environmental challenges. Its cultivation and processing promote responsible agricultural practices, which are recognised by recognised certifications.