Hemp growing and expertise

Fibre of the future, European hemp is a privileged territory for research and innovation. The challenges of developing its productivity and adapting it to the transformation of the markets are in full development.

Fibre of the future, European hemp is a privileged territory for research and innovation. The challenges of developing its productivity and adapting it to the transformation of the markets are in full development.

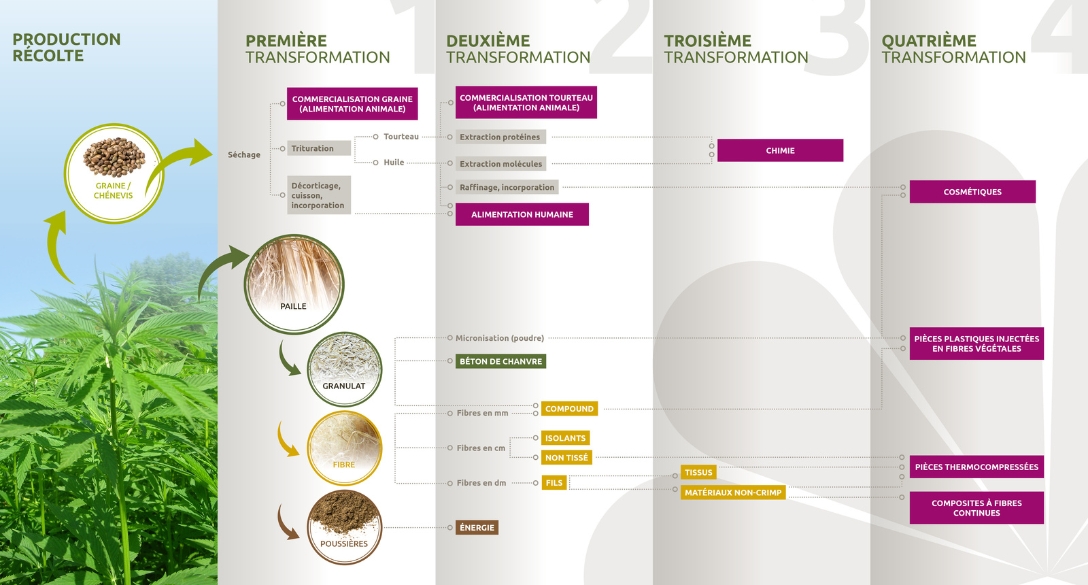

Sowing, retting, defibration, spinning… The stages of hemp cultivation are varied and depend on the desired finished product.

A spring crop, hemp is sown in April-May and harvested from late August to October. It is a fast-growing crop that reaches an average of 3 to 4m high depending on the variety.

The steps consist in transforming the fibers resulting from defibration into intermediate products. Vegetable fibers are used in the form of short fibers mixed with a polymer matrix to obtain “compounds” (granules) but also nonwovens and insulation.

Defibration consists in separating by a striking action, the fibers which surround the stem of the hemp located in the center of the stem. On leaving the defibration, the fibers are still encumbered with pectins and lignins: they will have to be cleaned for textile use and undergo pre-treatment actions.

Used by the flax sector, scutching makes it possible to obtain long fibres. It is being developed for hemp. It depends in particular on the adaptation of agricultural machinery capable of cutting straw to the length of flax stalks.

For an homogeneous retting, the operation consists of parallelizing the stalks to the field so that the alternating rain and sunshine degrades the pectin which clutter the fibres. Next comes the scutching step, which extracts the fibres from the stalk.

The type of transformation process impacts the type of fibers obtained.

Several pretreatments to prepare the fibre for spinning exist. We can cite degumming, carding or combing which prepares the fibre for spinning. It is the length of the fibre that will determine the choice of spinning mill and the quality of the yarn obtained, and therefore the potential applications of hemp.

These transformation processes are under development and do not have the same level of industrial maturity. The technical itineraries are very different for each process.

Weaving involves interlacing warp threads (which run lengthwise) with weft threads (which run widthwise) to create a fabric. The various weaving methods make it possible to produce different fabrics both in their appearance and in their textures.

Produced on circular machines then cut and sewn for knitwear collections, knitting provides flexibility and elasticity. “Knitting” comes from rectilinear machines capable of creating shaped, ready-to-assemble or seamless 3D pieces.

{{message}}