Everything you need to know about European flax

Flax, the plant source of the fibre, is grown on a wide swath of coastal land in Western Europe stretching from Normandy (France) to Amsterdam. Its high-quality results from a naturally humid climate and producers’ know-how over thousands of years. Its production is deeply rooted in the area.

Flax, a bio-based material

Bio-based products come from the living world and flax is an example. This plant fibre allows for the extraction of molecules and materials for the manufacture of a variety of products.

Flax and flax fibre classification

A distinction between the two important flax families was made at the end of the 19th century. Fibre flax, promoted by the Alliance, is distinct from oilseed flax.

flax fibre

Fibre flax

The properties of flax fibre

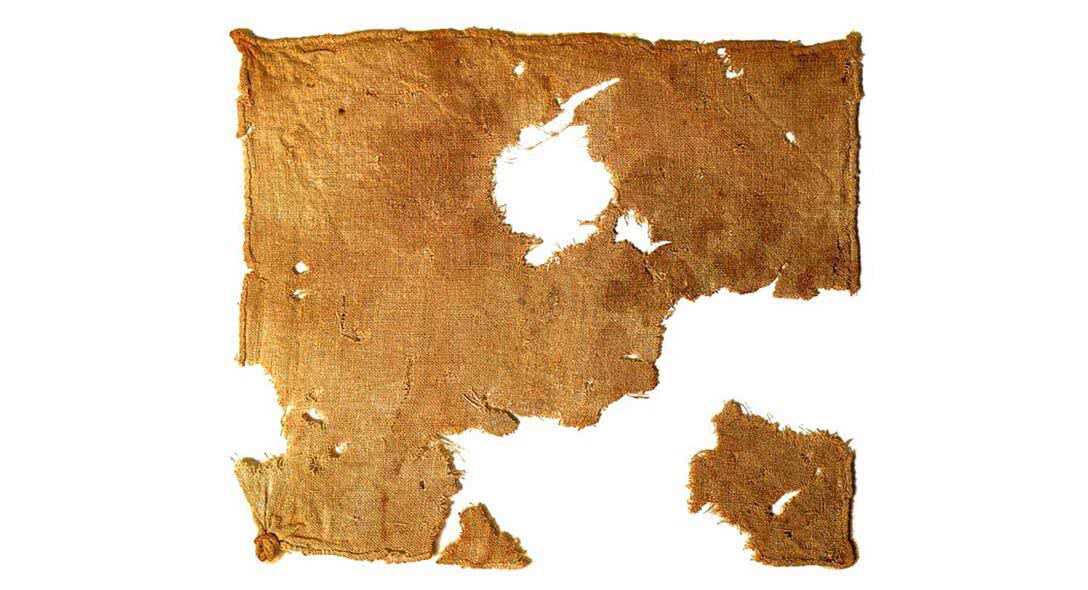

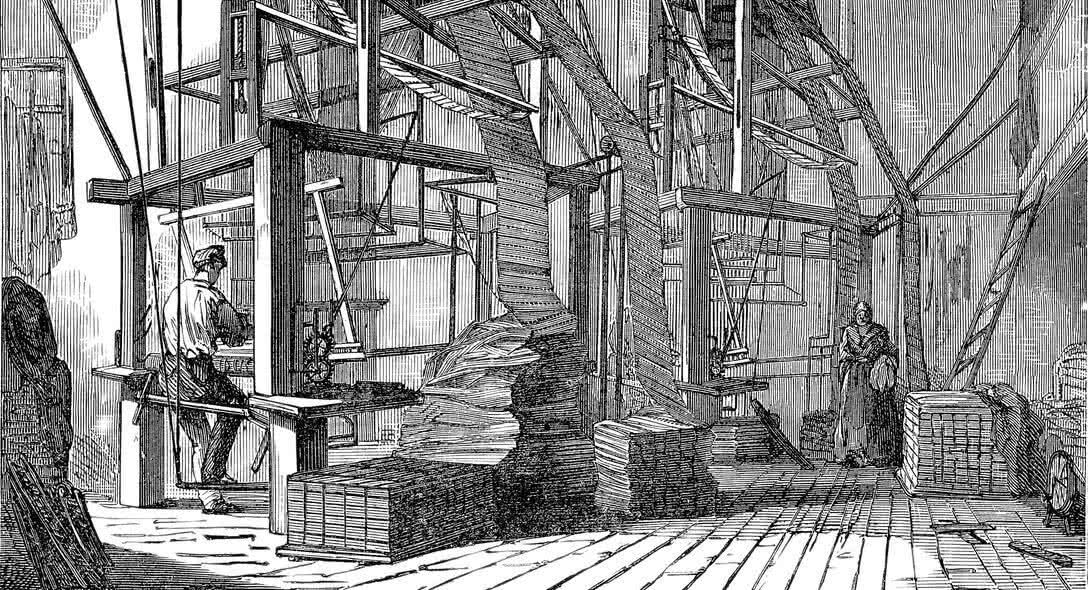

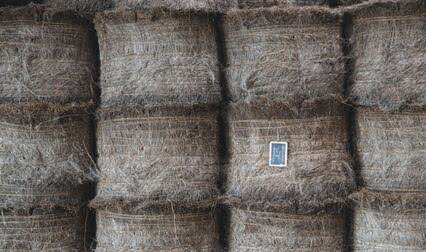

Flax fibres are known as bast fibres, indicating they are taken from the stems of plants and not their flowers. After the harvest, flax farmers bale the flax and transport it to the scutching mill. On site, workers operate machines to extract the scutched flax fibre.

The precise movements of the workers go hand in hand with the precision of their machines. While the textile industry prefers long fibres, it also uses short fibres for certain products.

Both types of fibres (long and short) can be found in flax composites. Short fibres are notably used in insulation materials, paper products and even banknotes.

Shives can be used for mulch, fuel and animal bedding. As for flax seeds, they can be reused for planting the next crop or processed to produce nonedible products such as solvents and oils.

The uses of flax fibre

The textile sector prefers to use the longest flax fibres. They have a myriad of properties: they are soft, strong, moisture absorbent and thermoregulating. Through their work and commitment to research and innovation, European spinners and weavers can obtain a wide variety of yarn textures. This lends itself to use in all hybridisations and finishes.

Jersey, knitted on circular knitting machines and then cut and sewn, is typically used to make T-shirts. Oiled linen cloth can be used to produce clothing and equipment for outdoor use which helps to enhance its water repellent properties.

Oilseed flax

The properties of flaxseed

The seeds of the plant can be crushed to extract their oil which can then be used in nonedible industrial applications and as an energy source. The meal co-product is used as animal fodder.

The uses of flaxseed

Linseeds are used mainly in animal feed. Rich in lipids, they are also used in the production of edible oils and cosmetics.

Flax, a responsible fibre

Flax fibre is characterised by circularity: 100% of the plant is valued.

Flax production areas

Linen-Flax is grown in Western Europe, on a wide coastal strip stretching from southern Normandy to northern France, from Belgium to the Netherlands. The naturally humid oceanic climate, the generous soils and the historic flax growers’ know-how contribute to the European flax quality. Today, 3/4 of the scutched flax fibre world's production comes from Western Europe, and France is the world leader in its production. A sector of excellence, the flax industry creates skilled local agricultural and industrial jobs in Europe, in compliance with international labour standards.

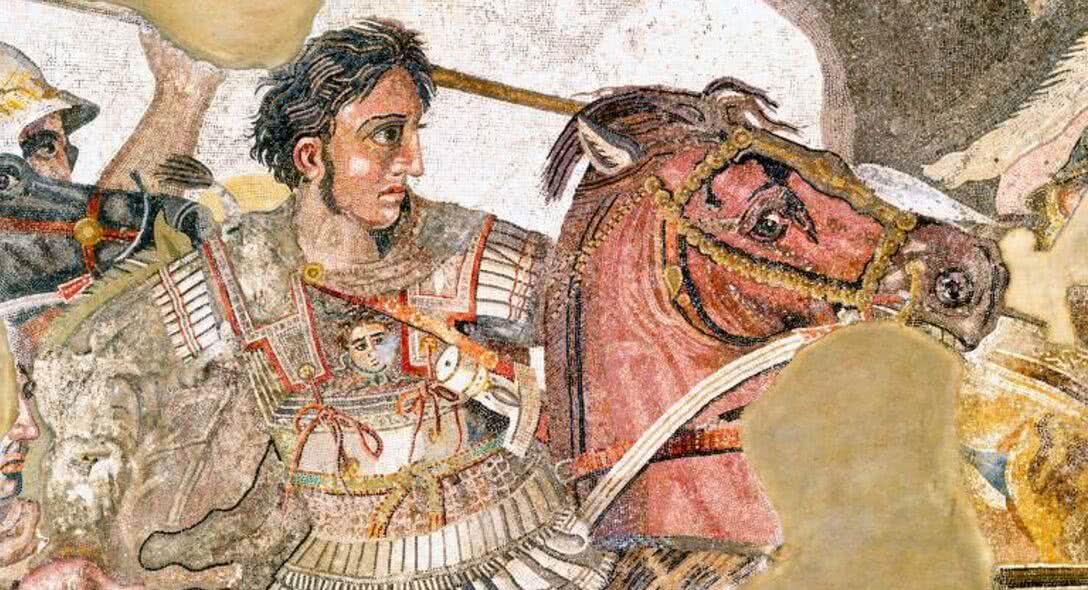

Linen, Fibre of Civilisation(s)

Collective work under the direction of Alain Camilleri

Co-publishing Actes Sud / Alliance for European Flax-Linen & Hemp

Linen, Fibre of Civilisation(s) is a ground-breaking collective work that brings together the expertise of archaeo-botanists, archaeologists, historians, scientific laboratories, designers, and industrialists, with European farmers, scutchers, spinners and weavers. The book highlights the multiple identities of flax-linen and its millennia-long history. It's a richly illustrated saga, with an editorial approach that illustrates the original dialogue between past and present. The book also highlights another topicality, a reputation inversely proportional to its weight in the world's textile fibre supply - less than 0.5% - whose international craze bears witness to consumers expectations in search of ethics and traceability, sustainable development, and a renewable resource.

{{message}}